Industrial emissions, from factories and power plants, are major contributors to air pollution. These emissions contain a variety of gases, including sulfur dioxide, nitrogen oxides, carbon monoxide, and volatile organic compounds. Exposure to these gases can cause respiratory problems, cardiovascular disease, and even cancer. To mitigate the impact of these pollutants on human health and the environment, effective industrial emission control strategies are necessary. Gas sensors play a critical role in monitoring and controlling industrial emissions. In recent years, innovations in gas sensor technology have revolutionized the field, offering more accurate, reliable, and cost-effective solutions. This article explores the key innovations in gas sensor technology and their impact on industrial emissions control.

- Selectivity and Sensitivity

Industrial emission control requires accurate identification and measurement of specific gases. Traditional gas sensors were often prone to cross-sensitivity, where they responded to multiple gases, leading to inaccurate results. However, innovations in gas sensor technology have improved the selectivity and sensitivity of sensors, enabling more precise detection and measurement of target gases.

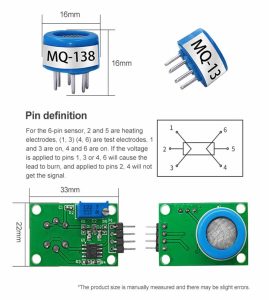

Newer gas sensor technologies, such as metal oxide-based sensors and electrochemical sensors, offer higher selectivity to specific gases. These sensors employ innovative materials and designs to enhance their sensitivity, allowing for precise measurements even at low concentrations. This improved selectivity and sensitivity enables accurate identification of pollutant sources and facilitates targeted mitigation efforts.

- Real-time Monitoring

Real-time monitoring of industrial emissions is critical for effective control and prevention of air pollution. Traditional gas sensors often required manual sampling and laboratory analysis, resulting in delays in obtaining data. However, recent innovations in gas sensor technology have led to the development of real-time monitoring systems that provide continuous, instantaneous data.

These real-time monitoring systems utilize wireless communication and data processing technologies to transmit and analyze data in real-time. This enables quick identification of emission sources, rapid response to emergencies, and adaptive control strategies. The ability to monitor emissions in real-time also provides valuable data for optimizing industrial processes and reducing emissions.

- Internet of Things (IoT) Integration

The integration of gas sensor technology with the Internet of Things (IoT) has revolutionized industrial emission control. IoT-enabled gas sensors can connect to wireless networks, allowing for real-time data transmission and remote monitoring. These interconnected sensors create extensive monitoring networks that provide comprehensive coverage of industrial emissions in large areas.

By combining data from multiple sensors, IoT-based systems can generate high-resolution pollution maps, identify pollution hotspots, and track pollutant dispersion patterns. This information is invaluable for optimizing industrial processes, identifying areas for emissions reduction, and developing evidence-based strategies for improving air quality. Furthermore, IoT integration enables seamless data sharing, empowering researchers and policymakers to collaborate and develop effective industrial emission control policies.

- Artificial Intelligence (AI)

Artificial Intelligence (AI) has emerged as a powerful tool for industrial emission control. AI algorithms can process large amounts of data from gas sensors and other sources, enabling quick identification of emission sources and proactive control measures. AI models can learn from historical data and predict future trends, facilitating proactive mitigation efforts.

AI-based industrial emission control systems can optimize industrial processes, reduce emissions, and ensure compliance with regulatory requirements. These systems use advanced analytics and machine learning algorithms to identify opportunities for emissions reduction, predict the impact of control measures, and optimize resource allocation.

- Gas Sensor Networks

Gas sensor networks enable comprehensive monitoring of industrial emissions, providing a holistic understanding of the composition and sources of pollutants. These networks consist of multiple gas sensors deployed throughout an industrial site, connected through wireless communication.

Gas sensor networks can detect pollutant plumes, track the movement of emissions, and identify emission sources. This information enables targeted mitigation efforts, such as optimizing industrial processes and refining emissions control strategies. Gas sensor networks also provide valuable data for compliance reporting and regulatory compliance.

Conclusion

Innovations in gas sensor technology have revolutionized the field of industrial emission control, offering more accurate, reliable, and cost-effective solutions. Improved selectivity and sensitivity of sensors ensure precise identification of specific pollutants, facilitating targeted mitigation efforts. Real-time monitoring and IoT integration enable comprehensive coverage of industrial emissions, providing valuable insights for optimizing industrial processes and reducing emissions. AI-based industrial emission control systems offer proactive mitigation measures, ensuring compliance with regulatory requirements. Gas sensor networks enable holistic understanding of industrial emissions, facilitating evidence-based strategies for improving air quality. As gas sensor technology continues to advance, it holds immense potential for promoting sustainable industrial development and mitigating the impact of industrial emissions on human health and the environment.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com