Workplace safety is a top priority for employers across industries. Among the various hazards that workers face, exposure to toxic gases can be particularly dangerous and even life-threatening. It is crucial to have effective measures in place to detect and mitigate these risks. Gas sensors are invaluable tools that play a vital role in enhancing workplace safety. In this article, we will explore the importance of gas sensors in identifying and monitoring hazardous gases, their applications in different work environments, and the impact they have on safeguarding employees' health and well-being.

Identifying Hazardous Gases:

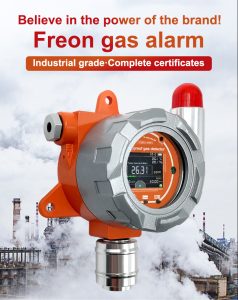

Gas sensors are designed to detect the presence of specific gases in the surrounding environment. They can identify a wide range of hazardous gases, such as carbon monoxide (CO), methane (CH4), hydrogen sulfide (H2S), ammonia (NH3), and many more. By continuously monitoring the air quality in workplaces, gas sensors provide early warnings about the presence of toxic gases, giving employees and employers the opportunity to take immediate action and prevent any potential harm.

Real-time Gas Monitoring:

Gas sensors offer real-time monitoring capabilities, allowing for instant detection and response to hazardous gas leaks or accumulations. These sensors are often integrated into advanced monitoring systems that provide continuous readings and alerts. When gas levels exceed predetermined thresholds, alarms are triggered, alerting workers and supervisors to evacuate the area, initiate emergency protocols, and address the issue promptly. Real-time gas monitoring helps minimize the risk of exposure, ensuring a safer work environment.

Application in Various Work Environments:

Gas sensors find applications in a wide range of work environments where toxic gases may be present. These include manufacturing facilities, chemical plants, laboratories, construction sites, confined spaces, and underground mines, among others. Each industry has its own set of potential gas-related hazards, and gas sensors can be customized to detect the specific gases relevant to each workplace. This versatility makes gas sensors an essential component of safety protocols across industries.

Preventing Accidents and Health Risks:

Gas leaks or accumulations in workplaces can lead to accidents, fires, explosions, and severe health risks for employees. The presence of toxic gases, even at low levels, can cause respiratory problems, organ damage, loss of consciousness, or even fatalities. By providing early warning signs, gas sensors enable workers to evacuate hazardous areas promptly, preventing accidents and minimizing the risk of exposure to harmful gases. This proactive approach significantly reduces the likelihood of injuries and illnesses in the workplace.

Compliance with Safety Regulations:

Workplace safety regulations and standards require employers to implement appropriate measures to protect employees from hazardous substances. Gas sensors are an essential tool for complying with these regulations. They provide tangible evidence of a proactive approach to workplace safety and demonstrate a commitment to employee well-being. By investing in gas detection systems, employers not only fulfill their legal obligations but also create a culture of safety and instill confidence among their workforce.

Maintenance and Calibration:

To ensure the accuracy and reliability of gas sensors, regular maintenance and calibration are essential. Periodic checks and calibration of gas sensors help maintain their sensitivity and responsiveness to the target gases. This ensures that the sensors provide accurate readings and reliable alerts when hazardous gas levels exceed the safety thresholds. Proper maintenance and calibration also extend the lifespan of the sensors, making them a cost-effective investment in long-term workplace safety.

Continuous Improvement of Safety Measures:

Gas sensors not only detect hazardous gases but also provide valuable data for analysis and continuous improvement of safety measures. By collecting and analyzing gas concentration trends over time, employers can identify patterns, potential sources of gas leaks, or areas prone to high gas concentrations. This information can be used to improve ventilation systems, modify work processes, implement additional safety measures, or enhance training programs, further minimizing the risk of gas-related incidents.

Conclusion:

Gas sensors are indispensable tools in enhancing workplace safety. By identifying hazardous gases, offering real-time monitoring, and enabling prompt response to gas leaks or accumulations, these sensors significantly reduce the risk of accidents, injuries, and illnesses in various work environments. Employers who invest in gas detection systems demonstrate their commitment to employee well-being and comply with safety regulations. With regular maintenance and calibration, gas sensors provide accurate readings and contribute to the continuous improvement of safety measures. Ultimately, the implementation of gas sensors helps create a safer work environment where employees can perform their tasks with confidence and peace of mind.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com