A wall-mounted O2 gas detector is a device used to monitor the concentration of oxygen gas in the air. It is designed to be installed on walls or other fixed surfaces in various industrial settings, such as factories, laboratories, warehouses, and storage facilities. In this article, we will explore the features, operation, benefits, and applications of a wall-mounted O2 gas detector.

A wall-mounted O2 gas detector typically consists of several key components that work together to detect and measure the concentration of oxygen gas. These components include a gas sensor, control panel, alarm system, and power supply.

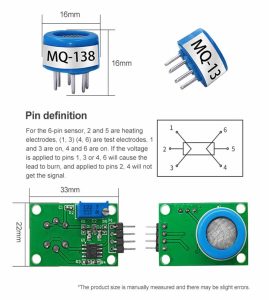

The gas sensor is the heart of the O2 gas detector. It is responsible for sensing the presence and measuring the concentration of oxygen in the surrounding air. There are different types of gas sensors used in O2 detectors, such as electrochemical sensors and optical sensors. Electrochemical sensors work by detecting changes in electrical currents generated when oxygen reacts with specific chemicals. Optical sensors use light absorption or emission properties of oxygen gas to determine its concentration. The sensor is usually housed in a protective casing to prevent damage or contamination.

The control panel is where the user can configure and monitor the O2 gas detector. It typically consists of a display screen, user-friendly interface, and control buttons. The display screen shows real-time oxygen levels, alarm status, and other relevant information. The user can set alarm thresholds, calibration parameters, and other settings through the control panel. Some advanced O2 gas detectors even offer remote monitoring and control capabilities, allowing users to access and manage the detectors from a computer or mobile device.

The alarm system is a critical feature of the O2 gas detector, designed to alert users when the oxygen concentration exceeds predefined limits. The alarm system typically includes audible and visual alarms. The audible alarm produces a loud sound, often a siren, to attract attention. The visual alarm may be in the form of flashing lights or a prominent display on the control panel. In some cases, the O2 gas detector may also have additional alarm outputs to trigger external devices, such as strobe lights or emergency shutdown systems.

The power supply provides the necessary electrical energy to operate the O2 gas detector. It can be powered by standard AC power or battery. Battery-powered O2 gas detectors are beneficial in areas with unreliable or no power supply. The power supply should be chosen based on the specific needs and requirements of the installation location.

Now let's discuss the benefits and applications of a wall-mounted O2 gas detector.

The primary benefit of using a wall-mounted O2 gas detector is the enhanced safety it provides. Oxygen gas is odorless, colorless, and tasteless, making it difficult to detect without specialized equipment. In environments where oxygen levels can fluctuate or drop to dangerous levels, such as confined spaces or areas with potential oxygen depletion, an O2 gas detector acts as an early warning system. It can quickly detect and alert users to oxygen deficiency, allowing them to take appropriate actions, such as donning protective equipment or evacuating the area.

Another benefit of a wall-mounted O2 gas detector is its continuous monitoring capability. Unlike manual gas sampling, which requires periodic checks, a wall-mounted gas detector continuously monitors oxygen levels in real-time. This ensures that any changes in oxygen concentration are immediately detected, providing a higher level of safety and reducing the risk of exposure to low oxygen levels.

The applications of wall-mounted O2 gas detectors are widespread across various industries. They are commonly used in industrial settings where oxygen levels can fluctuate or be hazardous, such as manufacturing plants, chemical processing facilities, and storage areas for flammable materials. O2 gas detectors are also utilized in laboratories where oxygen-sensitive experiments or processes are conducted. Additionally, they find application in confined spaces like tanks, silos, and tunnels, where the risk of oxygen depletion is high.

In conclusion, a wall-mounted O2 gas detector is a vital tool for ensuring safety in industrial environments. It monitors the concentration of oxygen in the air, providing continuous real-time data and alerting users to potential hazards. By detecting oxygen deficiency or excess, the gas detector helps prevent accidents, protect personnel, and comply with safety regulations. Investing in a wall-mounted O2 gas detector is a proactive measure towards maintaining a safe working environment.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com