Background:

Combustible gas has certain diffusion characteristics. In order to prevent accidents caused by flammable gas leakage, the key is to effectively control its continuous diffusion. Moreover, flammable gases will spread rapidly under the action of external forces. As a result, fires and explosions occur. How can such accidents be prevented? What we need to do is to constantly check the concentration of combustible gas. Once the concentration exceeds the standard, alarm quickly and take action at the first time. Therefore, combustible gas detector plays an important role in ensuring life and production.

How does the combustible gas detector work?

Combustible gas detector is a gas leak detector that can monitor the concentration of single or multiple combustible gases and issue an alarm. The combustible gas detector can be divided into catalytic type and infrared optical type according to its working principle.

The catalytic combustible gas detector is based on the resistance change of refractory platinum wire after heating to measure the combustible gas concentration. When the combustible gas enters the detector, it will cause an oxidation reaction (flameless combustion) on the surface of the platinum wire. The resulting heat will cause the temperature of the platinum wire to rise. The electrical resistivity of the platinum wire then changes, and the detected data changes and alerts are issued.

Infrared optical combustible gas detector is the use of infrared sensor, according to the absorption principle of infrared light source, to monitor the combustible gas in the field environment. When the gas passes through the infrared beam, the beam will be distorted, and the gas detector will determine what kind of gas is according to the distortion of the light.

Infrared sensor and catalytic sensor are commonly used in combustible gas detector, each sensor has its advantages and disadvantages. Infrared sensors are more durable and last longer because they are not in direct contact with gas. In addition, it requires less calibration because the gas detector can constantly readjust the beam. The catalytic sensor is less susceptible to dust and dirt, so it can monitor most hydrocarbons and hydrogen. And it is not affected by humidity, condensation, pressure or temperature. Therefore, we need to fully understand their advantages and disadvantages, according to the actual application to choose the most suitable combustible gas detector.

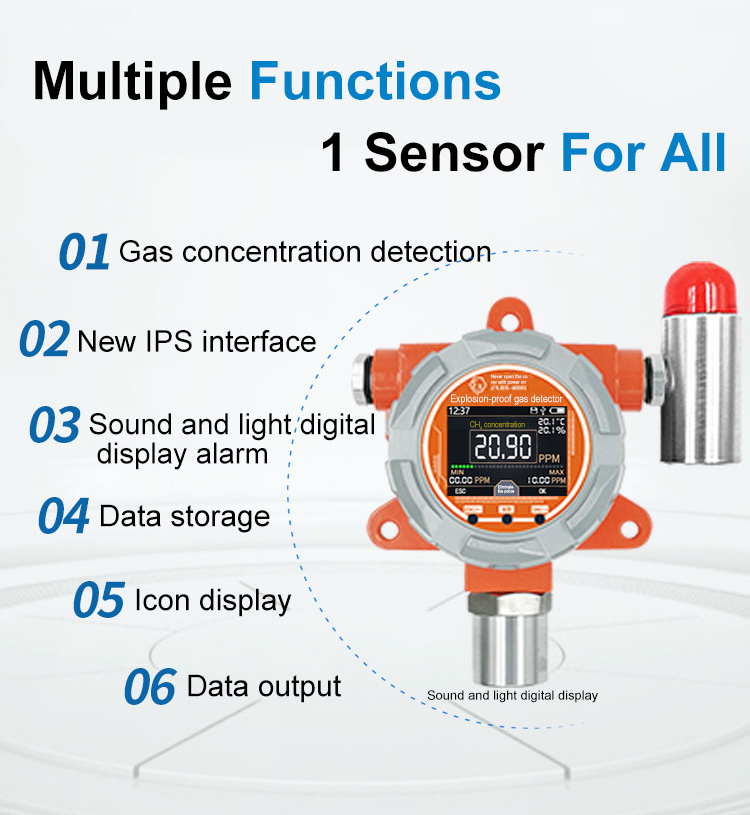

Fixed CH4 gas sensor- Methane gas alarm detector-CH4 monitor

The Fixed methane gas sensor adopts industrial-grade high-definition interface, and the shell adopts die-casting aluminum technology. It has the advantages of waterproof, dustproof, explosion-proof and anti-condensation. 15 seconds quick response, more accurate detection, guaranteed life.

High-definition LCD color screen display, industrial-grade high-definition interface, intuitive display with 320*240 resolution; Multi-machine selection of alarm controller, rich in optional external control ports, easy to use, sound and light alarm; Waterproof, dustproof, explosion-proof, anti-condensation, the shell adopts die-cast aluminum technology, waterproof. IP65 waterproof.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com