Gas detectors are crucial devices used in various industries and settings to monitor and detect potentially dangerous gases. Whether it's a chemical plant, oil refinery, mining site, or confined space, gas detectors play a vital role in ensuring the safety of workers, preventing accidents, and maintaining a secure working environment. This article aims to provide an in-depth understanding of gas detectors, their functionality, types, applications, and their significance in industrial safety.

Types of Hazardous Gases:

Hazardous gases can include combustible gases, toxic gases, asphyxiants, and volatile organic compounds (VOCs). Each type poses different risks and requires specific detection methods. a. Combustible Gases: Gases that can ignite and cause fires or explosions, such as methane, propane, and hydrogen. b. Toxic Gases: Gases that can harm human health or cause fatalities, including carbon monoxide, hydrogen sulfide, ammonia, and chlorine. c. Asphyxiants: Gases that displace oxygen and lead to suffocation, like nitrogen, carbon dioxide, and argon. d. VOCs: Organic compounds that can be harmful when released into the air, such as benzene, toluene, and xylene.

Sources of Gas Emissions:

Hazardous gases can originate from various sources, including industrial processes, chemical reactions, fuel combustion, storage tanks, pipelines, confined spaces, and manufacturing activities. Identifying potential gas emission sources is crucial for implementing effective gas detection measures.

II. Importance of Gas Detectors in Industrial Safety:

Early Warning System: Gas detectors act as an early warning system by continuously monitoring the air for the presence of hazardous gases. Once the concentration of a gas surpasses a pre-set threshold, the detector triggers alarms, alerts, and safety protocols to prevent exposure and mitigate risks.

Personal Safety:

Gas detectors protect personnel from inhaling toxic fumes, experiencing oxygen depletion, or being exposed to flammable or explosive environments. By promptly detecting gas leaks or accumulation, these devices reduce the likelihood of accidents, injuries, and fatalities.

Compliance with Regulations:

Regulatory authorities and industry standards require the use of gas detection systems to ensure compliance with occupational safety and health regulations. Implementing gas detectors helps companies meet legal requirements and maintain a safe working environment for their employees.

III. Types of Gas Detectors:

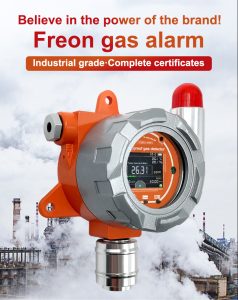

Fixed gas detectors are permanently installed in specific locations to provide continuous monitoring of gas concentrations. They are commonly used in industrial settings where gas hazards are persistent or frequent.

Portable Gas Detectors:

Portable gas detectors are handheld devices that allow users to move around and monitor gas levels in different areas. They are essential for personal safety, confined space entry, and quick spot checks.

Single-Gas Detectors:

Single-gas detectors are designed to detect and monitor the concentration of a specific gas. They are typically small, compact, and cost-effective.

Multi-Gas Detectors:

Multi-gas detectors can monitor multiple gases simultaneously. They are versatile devices suitable for environments with potential exposure to various hazardous gases.

IV. Gas Detection Technologies:

Catalytic Bead Sensors: Catalytic bead sensors are commonly used for detecting combustible gases. The sensor contains a heating element and two platinum wire coils coated with a catalyst. When a combustible gas reacts with the catalyst, it produces heat, changing the resistance of the coil and triggering an alarm.

Electrochemical Sensors:

Electrochemical sensors are effective for detecting toxic gases. They use a chemical reaction between the target gas and an electrolyte solution to generate an electrical signal proportional to the gas concentration.

Infrared Sensors:

Infrared sensors are suitable for detecting combustible gases and certain toxic gases. They work by measuring the absorption of infrared radiation by the gas molecules in the sample.

Photoionization Detectors (PID):

PID sensors are capable of detecting a wide range of volatile organic compounds (VOCs). They use ultraviolet light to ionize gas molecules, creating a measurable current that corresponds to the gas concentration.

V. Applications of Gas Detectors:

Gas detectors are extensively used in the oil and gas industry to monitor hydrocarbon emissions, detect flammable gases, and ensure worker safety in drilling operations, refineries, petrochemical plants, and offshore platforms.

Chemical Manufacturing:

Chemical manufacturers rely on gas detectors to identify airborne chemical releases, monitor solvent concentrations, and prevent exposure to toxic gases in laboratories, production facilities, and storage areas.

Mining:

In mining operations, gas detectors are vital for detecting methane and other explosive gases in underground mines, helping prevent mine explosions and ensuring the safety of miners.

Confined Spaces:

Gas detectors play a critical role in confined space entry, such as tanks, vessels, sewers, and tunnels. They help identify potentially hazardous atmospheres and ensure the safety of workers entering these confined areas.

VI. Calibration and Maintenance of Gas Detectors:

Regular calibration and maintenance are essential to ensure accurate and reliable performance of gas detectors. Calibration verifies sensor accuracy, sensitivity, and response time, while maintenance includes sensor replacement, battery checks, and functional testing.

VII. Challenges and Future Developments:

Gas detectors may sometimes trigger false alarms due to environmental factors, cross-interference with other gases, or sensor malfunctions. Ongoing research aims to minimize false alarms and improve overall detector reliability.

Wireless Connectivity and IoT:

Advancements in wireless communication and the Internet of Things (IoT) enable the integration of gas detectors with centralized monitoring systems. This allows for real-time data collection, analysis, and remote alarms, enhancing safety management and response capabilities.

Conclusion:

Gas detectors are indispensable devices that ensure safety in hazardous environments. By continuously monitoring the air for the presence of dangerous gases, they provide early warnings, protect workers, and prevent accidents. With advancements in technology and ongoing research, gas detectors will continue to evolve, improving their accuracy, reliability, and integration with other safety systems. Implementing effective gas detection measures remains a fundamental aspect of industrial safety, safeguarding lives, assets, and the environment.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com