Ensuring workplace safety is of paramount importance in industries where workers are exposed to various hazardous substances and potentially dangerous environments. In recent years, gas sensors have emerged as a revolutionary technology in enhancing industrial safety measures. These sensors play a crucial role in detecting and monitoring the presence of toxic gases, helping to prevent accidents, protect workers, and maintain a safe working environment. This article will explore how gas sensors have revolutionized industrial safety measures and discuss their impact on different sectors.

Importance of Industrial Safety

Industrial safety is essential for safeguarding workers' well-being, reducing accidents, and preventing potential disasters. Without proper safety measures, workers can be exposed to toxic gases, combustible materials, and other hazardous conditions that pose significant risks. By integrating advanced gas sensor technology into industrial safety systems, companies can proactively monitor the work environment, detect gas leaks or abnormal conditions, and mitigate potential dangers before they escalate.

Evolution of Gas Sensor Technology

Gas sensor technology has evolved significantly over the years, making tremendous strides in terms of accuracy, sensitivity, and efficiency. Modern gas sensors are capable of detecting a wide range of gases, including but not limited to ammonia, carbon monoxide, hydrogen sulfide, methane, and volatile organic compounds. The following are some notable advancements in gas sensor technology:

2.1 Miniaturization and Portability

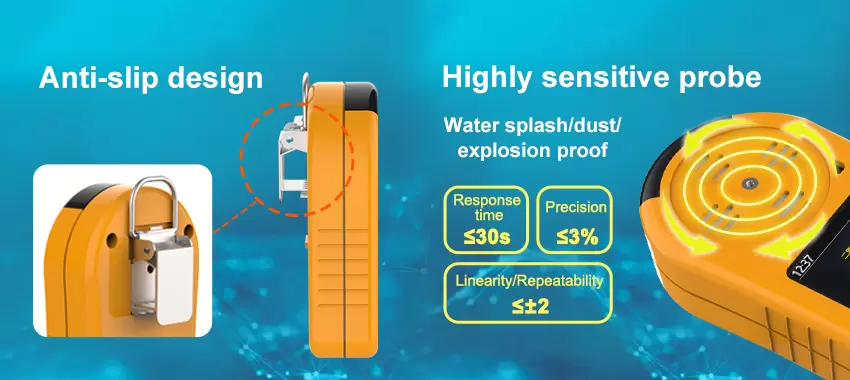

One significant advancement in gas sensor technology is the miniaturization of sensors. Previously, gas sensors were large and cumbersome devices, limiting their usability in certain environments. However, with miniaturization, gas sensors have become more compact and portable, enabling their integration into wearable devices, handheld detectors, and even personal protective equipment. This portability allows workers to carry gas sensors with them, providing real-time information about the surrounding air quality.

2.2 Wireless Connectivity

Integration with wireless communication technologies has revolutionized the way gas sensors operate and provide data. Wireless-enabled gas sensors can transmit real-time measurements to a central monitoring system, allowing supervisors and safety personnel to remotely monitor multiple locations simultaneously. This connectivity enables quicker responses to emergencies or abnormal conditions, improving overall industrial safety.

2.3 Selectivity and Sensitivity

Gas sensors now possess enhanced selectivity, enabling them to differentiate between target gases and other compounds that may interfere with accurate detection. Manufacturers have developed sensor technologies that are highly specific to particular gases, reducing false alarms and increasing reliability. Additionally, gas sensors have become more sensitive, capable of detecting gases at lower concentrations, which is crucial for ensuring workers' safety in environments where even minuscule gas leaks can be hazardous.

2.4 Data Logging and Analysis

With the integration of gas sensors into data logging and analysis systems, large volumes of sensor data can be collected and analyzed. This data-driven approach allows for the identification of long-term trends, patterns, and anomalies. By utilizing machine learning algorithms, these systems can predict potential safety hazards, aiding in proactive safety measures and preventing accidents before they occur.

Impact on Industrial Sectors

The revolution brought about by gas sensors has had a significant impact on various industrial sectors. Let's explore some specific applications:

3.1 Chemical and Petrochemical Industry

In the chemical and petrochemical industry, workers are exposed to a wide range of toxic and flammable gases. Gas sensors play a critical role in continuously monitoring gas levels, ensuring worker safety, and preventing potential accidents. They alert workers and supervisors when the concentration of a particular gas exceeds permissible limits or when leaks occur, allowing for immediate action to mitigate risks.

3.2 Mining Industry

The mining industry is known for its challenging work environment, with potential risks such as methane gas accumulation and underground explosions. Gas sensors are crucial in detecting the presence of methane, carbon monoxide, and other dangerous gases in mines, providing early warnings and enabling prompt evacuation or ventilation measures. By continuously monitoring gas concentrations, workers' safety can be significantly enhanced.

3.3 Manufacturing and Industrial Plants

In manufacturing and industrial plants, gas sensors are used to detect a variety of gases, such as ammonia, chlorine, hydrogen sulfide, and volatile organic compounds. These sensors play a vital role in ensuring worker safety, preventing chemical spills, and maintaining compliance with environmental regulations. Through real-time monitoring, prompt actions can be taken in case of gas leaks or abnormal conditions, minimizing the risk of workplace accidents.

3.4 Energy Industry

The energy industry, including power plants and natural gas facilities, heavily relies on gas sensors to maintain safety standards. Gas sensors are used to detect leaks, monitor air quality, and ensure the safe operation of equipment. By promptly identifying and addressing potential gas leaks or hazardous conditions, gas sensors help prevent catastrophic incidents, protect workers, and protect the environment.

Future Directions and Challenges

While gas sensors have revolutionized industrial safety measures, there are still challenges and areas for improvement:

4.1 Sensor Reliability and Maintenance

To ensure the accurate and reliable operation of gas sensors, regular maintenance, calibration, and sensor replacement are necessary. Developing automated maintenance and calibration systems can reduce reliance on manual tasks, ultimately improving the reliability of gas sensors.

4.2 Integration with Automation Systems

Integrating gas sensors with automation systems can enhance safety measures further. For example, gas sensors can be connected to shut-off valves or ventilation systems, enabling automated responses to abnormal conditions. This integration will help minimize human error and increase the efficiency and effectiveness of safety measures.

4.3 Multi-Gas Detection Capability

The ability to detect multiple gases simultaneously is an area that requires further development. As different industries may involve exposure to various gases, the capability to detect and differentiate between multiple gases in real-time would enhance overall safety measures.

4.4 Cost-Efficiency and Accessibility

The cost of advanced gas sensors can sometimes be prohibitive for smaller organizations or developing regions. Continued research and advancements in manufacturing processes can drive down the cost of gas sensors, making them more accessible to a broader range of industries.

Conclusion

Gas sensors have revolutionized industrial safety measures by enabling real-time detection and monitoring of toxic gases in various work environments. The advancements in technology, including miniaturization, wireless connectivity, selectivity, and sensitivity, have greatly enhanced the effectiveness and efficiency of these sensors. The impact of gas sensors extends across several industrial sectors, ensuring worker safety, preventing accidents, and maintaining compliance with safety regulations. However, continuous research, development, and improvements are necessary to overcome challenges and further enhance the reliability, integration, and cost-effectiveness of gas sensor technology. With ongoing advancements, gas sensors will continue to play a pivotal role in creating safer workplaces and protecting workers' well-being.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com