Workplace safety is a paramount concern for industries operating in hazardous environments. One of the critical aspects of ensuring safety is the detection and monitoring of harmful gases and vapors. Gas sensors have emerged as indispensable tools in industrial settings, offering real-time monitoring and early warning systems to mitigate potential risks. This article aims to explore the importance of gas sensors in ensuring workplace safety in industrial environments.

Understanding Workplace Hazards:

Industrial environments often contain a wide range of hazardous gases and vapors that pose significant risks to workers' health and safety. These hazards can include toxic gases like carbon monoxide (CO), hydrogen sulfide (H2S), ammonia (NH3), and volatile organic compounds (VOCs). Exposure to these gases can lead to respiratory problems, organ damage, and even fatalities. Therefore, it is crucial to implement effective gas detection systems to maintain a safe working environment.

The Role of Gas Sensors:

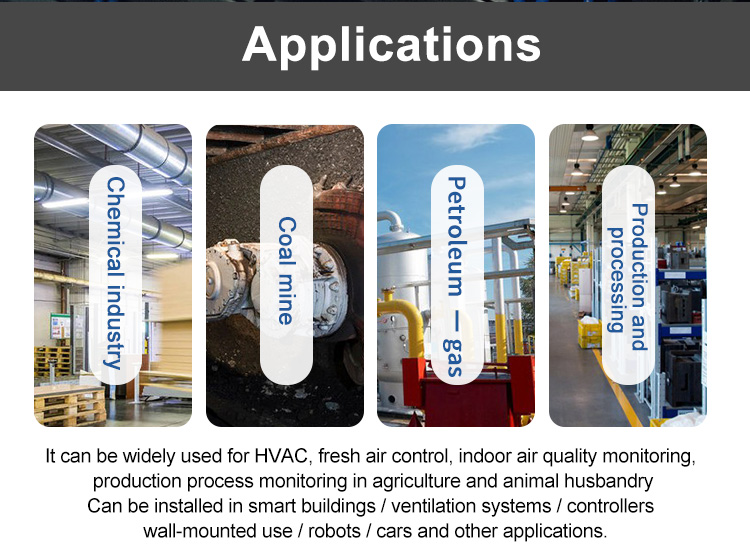

Gas sensors are essential devices employed to detect and monitor the presence of hazardous gases in industrial environments. These sensors utilize various technologies such as electrochemical, semiconductor, and infrared to measure gas concentrations accurately. They provide vital information about the type, level, and location of gas leaks and help prevent accidents by triggering alarms or initiating safety measures.

Fixed Gas Detection Systems:

Fixed gas detection systems are commonly used in industrial facilities to monitor gas levels continuously. Gas sensors are strategically placed in key locations to ensure comprehensive coverage. These systems are integrated with control panels and alarms that alert personnel when gas concentrations exceed predetermined thresholds. Fixed gas detection systems provide reliable and real-time data to enable prompt response and the implementation of necessary safety protocols.

Portable Gas Detectors:

In addition to fixed systems, portable gas detectors play a crucial role in maintaining workplace safety. These handheld devices allow workers to monitor gas levels in their immediate surroundings as they move around the facility. Portable gas detectors are particularly useful for confined spaces, remote locations, and areas with a higher risk of gas leaks. They provide workers with an additional layer of protection and help identify potential hazards in real-time.

Early Warning Systems:

Gas sensors also contribute to the development of early warning systems that provide timely alerts and enable efficient evacuation procedures. When gas concentrations exceed safe levels, gas sensors trigger alarms and activate emergency response protocols. This rapid response helps prevent accidents, minimize injuries, and safeguard the well-being of workers.

Calibration and Maintenance:

To ensure the accuracy and reliability of gas sensors, regular calibration and maintenance are essential. Gas sensors should be calibrated periodically to account for changes in environmental conditions and ensure accurate measurements. Additionally, routine maintenance and sensor replacement are necessary to prevent false alarms and maintain optimal performance.

Integration with Industrial Automation:

Gas sensors can be integrated with industrial automation systems to enhance workplace safety further. By incorporating gas sensor data into the overall control system, automated responses can be triggered, such as shutting down machinery, isolating affected areas, or activating ventilation systems. This integration helps mitigate risks and protect workers from exposure to hazardous gases.

Training and Education:

Utilizing gas sensors effectively requires proper training and education for workers. Employees should receive comprehensive training on gas detection systems, including how to interpret alarms, respond to emergencies, and follow safety protocols. Regular refresher courses will ensure that workers are well-prepared to handle potential gas-related incidents effectively.

Ongoing Research and Development:

Continued research and development in the field of gas sensors are crucial for improving workplace safety in industrial environments. Advancements in sensor technology, such as increased sensitivity, reduced response time, and enhanced selectivity, will further enhance the detection and monitoring capabilities. Furthermore, the integration of gas sensors with IoT platforms and data analytics will enable more efficient data collection, analysis, and predictive maintenance.

Conclusion:

Gas sensors play a vital role in ensuring workplace safety in industrial environments. By effectively detecting and monitoring hazardous gases, these sensors enable early detection, timely response, and the implementation of necessary safety measures. The integration of gas sensors with industrial automation systems further enhances workplace safety. Ongoing research and development will undoubtedly contribute to eve

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com