Harmful gases present a significant risk in various industrial settings, posing threats to worker safety, environmental impact, and overall operational efficiency. To address these challenges, gas sensors have emerged as indispensable tools for detecting and monitoring harmful gases in industrial environments. This article explores the role of gas sensors in industrial settings, their types, and their applications in ensuring a safe and healthy working environment.

Understanding the Importance of Gas Detection in Industrial Settings:

Industrial processes often involve the use of hazardous substances, which can lead to the release of harmful gases such as hydrogen sulfide (H2S), ammonia (NH3), carbon monoxide (CO), and volatile organic compounds (VOCs). Rapid detection and monitoring of these gases are crucial to prevent accidents, protect workers from exposure, and maintain compliance with safety regulations.

Gas Sensor Technologies:

Gas sensors utilize various technologies to detect and measure the presence of harmful gases. Common types of gas sensors used in industrial settings include electrochemical, catalytic, infrared, and metal-oxide semiconductor sensors. Each technology has its advantages and limitations, making it suitable for specific gas detection applications.

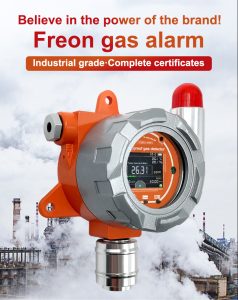

Fixed Gas Detection Systems:

In industrial settings, fixed gas detection systems are installed to continuously monitor the air quality and provide early warning of gas leaks or abnormal gas concentrations. These systems typically consist of multiple gas sensors strategically placed in key areas within the facility, such as storage areas, production floors, and confined spaces. When a gas leak is detected, alarms are triggered, and safety protocols are initiated to protect workers and mitigate potential hazards.

Hazards in Specific Industrial Sectors:

Gas sensors play a critical role in detecting harmful gases specific to various industrial sectors. For instance, in the oil and gas industry, gas sensors are used to detect and monitor the presence of combustible gases like methane (CH4). In chemical manufacturing plants, sensors are employed to monitor the release of toxic gases or volatile chemicals. Understanding the specific hazards in each sector allows for tailored gas detection solutions.

Portable Gas Detectors:

In addition to fixed gas detection systems, portable gas detectors are essential tools for industrial workers, providing personal protection and mobility. These compact devices allow workers to monitor their immediate surroundings for potential gas leaks or hazardous atmospheres. They are commonly used in confined spaces, construction sites, and maintenance activities, providing real-time data to ensure worker safety.

Calibration and Maintenance:

To ensure the accuracy and reliability of gas sensors, regular calibration and maintenance are crucial. Calibration involves comparing sensor readings to known gas concentrations to verify accuracy. Routine maintenance includes sensor cleaning, replacing consumables (such as filters), and checking for any signs of degradation. Proper calibration and maintenance practices are essential for maintaining sensor performance and prolonging their lifespan.

Integration with Automation Systems:

Modern industrial facilities often leverage automation systems and Internet of Things (IoT) technologies to enhance operational efficiency. Gas sensors can be integrated into these systems, allowing for real-time monitoring and data logging. This integration enables predictive maintenance, automated alarm notification, and data analysis for process optimization, ultimately improving safety and productivity.

Training and Safety Procedures:

Alongside the use of gas sensors, comprehensive training programs and safety procedures are crucial for the effective implementation of gas detection in industrial settings. Workers should be trained on proper equipment use, interpretation of gas sensor readings, emergency response protocols, and best practices for gas leak prevention. Regular safety drills and refresher trainings contribute to a safety-focused culture in the workplace.

Conclusion:

Gas sensors play a pivotal role in industrial settings by detecting and monitoring harmful gases, ensuring worker safety, and minimizing the environmental impact of industrial processes. Through the deployment of fixed detection systems and portable devices, industries can proactively identify and mitigate the risks associated with gas leaks and hazardous atmospheres. By integrating gas sensor data with automation systems, real-time monitoring and predictive maintenance become possible, improving operational efficiency. Combined with comprehensive training and safety procedures, gas sensors contribute to creating safer and healthier industrial environments for workers worldwide.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com