Industrial processes rely on the efficient and safe utilization of various gases. However, the presence of hazardous gases and volatile compounds can pose risks to both human health and the environment. Real-time gas sensors are cutting-edge devices that play a crucial role in optimizing industrial processes by providing accurate and timely data on gas concentrations. This article explores the significance of real-time gas sensor data in enhancing industrial operations and improving safety standards.

Importance of Gas Monitoring in Industrial Settings:

In many industries, gases such as methane, hydrogen sulfide, ammonia, and volatile organic compounds (VOCs) are employed or produced as part of manufacturing processes. Monitoring these gases is essential to ensure worker safety, prevent accidents, and maintain compliance with regulatory standards. Real-time gas sensors act as a vigilant line of defense by continuously measuring gas concentrations and alerting operators to potential hazards.

Real-time Gas Sensors: Accuracy and Reliability:

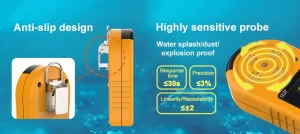

Real-time gas sensors are designed to deliver highly accurate and reliable data on gas concentrations. These sensors employ advanced technologies like electrochemical, infrared, or photoionization detection methods to detect and quantify specific gases. The real-time nature of the data allows for immediate action to be taken in response to changing gas levels.

Ensuring Worker Safety:

The primary objective of real-time gas sensors is to protect workers from exposure to hazardous gases. By monitoring gas concentrations in industrial environments, these sensors can promptly identify the presence of dangerous gases, enabling timely evacuation or the implementation of safety protocols. Continuous monitoring ensures that workers are protected from potentially life-threatening situations.

Preventing Equipment Failure and Production Downtime:

Certain gases can be corrosive or harmful to industrial equipment. Real-time gas sensors provide vital insights into the corrosiveness or toxicity of gases present in the production environment. By detecting the presence of corrosive gases, operators can take preventive measures to mitigate the risk of equipment failure or premature deterioration. This proactive approach helps avoid costly production downtime and maintenance activities.

Optimizing Process Efficiency:

Real-time gas sensor data is valuable for optimizing industrial processes and improving overall efficiency. By monitoring gas concentrations during production, operators can identify opportunities for process optimization, such as adjusting gas flow rates, fine-tuning reaction conditions, or implementing better control strategies. This optimization leads to improved product quality, reduced waste generation, and enhanced resource utilization.

Environmental Monitoring and Compliance:

Industries must adhere to strict environmental regulations to minimize their impact on the environment. Real-time gas sensors assist in monitoring emission levels and ensuring compliance with regulatory requirements. By continuously measuring gas concentrations, industries can identify sources of emissions and implement corrective actions to reduce their environmental footprint.

Early Leak Detection:

Leaks of hazardous gases can have severe consequences, including explosions, fires, or long-term health effects. Real-time gas sensors enable early leak detection, triggering alarms or alerts when gas concentrations exceed predetermined thresholds. This early warning system allows for prompt response measures to be implemented, minimizing the potential risks associated with gas leaks.

Integration with Industrial Automation:

Real-time gas sensors can be integrated into industrial automation systems to enhance overall process control and safety. By connecting gas sensors with control systems and programmable logic controllers (PLCs), automated responses can be triggered based on gas concentration levels. For example, if a gas exceeds safe limits, production can be automatically halted, ventilation systems can be adjusted, or emergency shutdown procedures can be activated.

Conclusion:

Real-time gas sensor data plays a pivotal role in optimizing industrial processes and ensuring the safety of workers and the environment. By continuously monitoring gas concentrations, these sensors provide valuable insights that enable proactive decision-making and the implementation of appropriate measures to prevent accidents, optimize production efficiency, and maintain compliance with regulatory standards. As industries continue to prioritize safety, efficiency, and sustainability, real-time gas sensors will prove indispensable in driving advancements in industrial processes and setting new standards for operational excellence.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com