Industrial safety is of paramount importance in sectors where workers are exposed to hazardous gases. The ability to detect and monitor these gases in real-time is crucial for preventing accidents, protecting worker health, and ensuring a safe working environment. Gas sensors have emerged as revolutionary tools in industrial safety, enabling accurate and efficient detection of hazardous gases. This article explores the significance of gas sensors in revolutionizing industrial safety and their role in hazardous gas detection.

Understanding the Importance of Industrial Safety:

Industrial workplaces often harbor potential hazards, including toxic or flammable gases. Exposure to these gases can lead to severe health consequences, fires, explosions, and even loss of life. Ensuring the safety and well-being of workers is not only an ethical responsibility but also a legal requirement in many countries.

The Role of Gas Sensors in Hazardous Gas Detection:

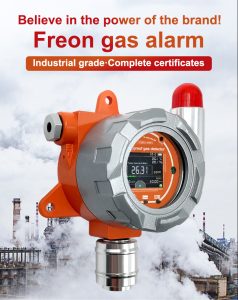

Gas sensors are devices designed to detect and monitor specific gases present in the environment. They provide real-time data on gas concentrations, allowing for early detection and prompt response to potential hazards. Gas sensors play a vital role in industrial safety by continuously monitoring the air quality, enabling effective mitigation strategies, and reducing the risk of accidents.

Detecting a Wide Range of Hazardous Gases:

Gas sensors can be tailored to detect various hazardous gases encountered in industrial settings. Common gases include methane, hydrogen sulfide, ammonia, carbon monoxide, volatile organic compounds (VOCs), and many others. By accurately identifying the presence and concentration of these gases, gas sensors enable proactive measures to prevent accidents and protect worker health.

Real-Time Monitoring and Alarm Systems:

Gas sensors provide real-time monitoring of gas levels, allowing for immediate action in case of alarm-triggering gas concentrations. When a hazardous gas surpasses a predefined threshold, the sensor sends signals to the central control system, activating alarms, and initiating emergency response protocols. Real-time monitoring coupled with rapid alarm systems ensures swift response and reduces the time for potential exposure.

Portable Gas Sensors for Mobile Monitoring:

In industries where workers are required to move across different locations, portable gas sensors are essential. These devices allow for mobile monitoring of hazardous gases, ensuring worker safety wherever they are in the facility. Portable gas sensors provide flexibility and versatility in detecting gases, enabling on-the-go hazard mitigation strategies.

Continuous Monitoring and Data Logging:

Gas sensors facilitate continuous monitoring of hazardous gases, capturing data over time. This data can be logged and analyzed to identify trends, potential sources of gas leaks, or areas prone to higher gas concentrations. Continuous monitoring provides valuable insights for safety managers to assess risks, implement preventive measures, and make informed decisions.

Integration with Industrial Control Systems:

Gas sensors can be integrated into industrial control systems, allowing for seamless communication and coordinated responses. When integrated, gas sensors can trigger automatic shutdowns, activate ventilation systems, or alert supervisors to take immediate action. The integration of gas sensors with control systems enhances operational efficiency and emphasizes the importance of real-time safety management.

Calibration and Maintenance:

To ensure reliable and accurate performance, gas sensors require periodic calibration and maintenance. Regular calibration guarantees the sensor's accuracy by aligning its readings with known gas concentrations. Routine maintenance includes sensor cleaning, replacement of consumables, and checking for any physical damages. Proper calibration and maintenance regimes are vital for maintaining the effectiveness of gas sensors in hazardous gas detection.

Advancements in Gas Sensing Technology:

The field of gas sensor technology is rapidly advancing, introducing new techniques and materials to improve detection capabilities. For example, nanomaterial-based gas sensors offer increased sensitivity and selectivity, leading to enhanced accuracy. Additionally, wireless connectivity and the Internet of Things (IoT) integration enable remote monitoring, automated alerts, and enhanced data analysis.

Conclusion:

Gas sensors are revolutionizing industrial safety by enabling reliable and efficient detection of hazardous gases. Through real-time monitoring, alarm systems, and integration with industrial control systems, gas sensors ensure timely responses to potential hazards. Portable gas sensors facilitate mobile monitoring, while continuous data logging provides insights for risk assessment and mitigation. As gas sensing technology continues to advance, it is imperative that industries prioritize the implementation and maintenanc

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com