Industrial emissions have become a significant concern, as they contribute to air pollution and have adverse effects on human health and the environment. To address this issue, gas sensor technology has emerged as a valuable tool for monitoring and analyzing industrial emissions. This article explores the importance of gas sensor technology in unlocking insights into industrial emissions, discussing its applications, benefits, and future developments.

Industrial Emissions and Air Pollution :

Industrial emissions refer to the release of pollutants into the atmosphere from industrial processes and activities. These emissions include greenhouse gases, particulate matter, volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur dioxide (SO2), and other harmful substances. Industrial activities such as manufacturing, power generation, and transportation contribute significantly to air pollution and climate change.

The Role of Gas Sensors in Monitoring Industrial Emissions :

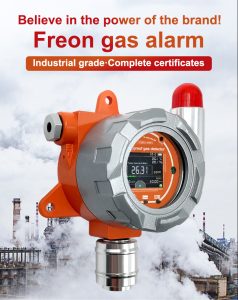

Gas sensors play a crucial role in monitoring and analyzing industrial emissions by detecting and quantifying various gases and pollutants. They provide real-time data and insights into emission sources, concentrations, and trends. Gas sensors can detect and measure gases such as carbon dioxide (CO2), methane (CH4), sulfur dioxide (SO2), nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter.

Gas sensors find applications in various industrial sectors, including manufacturing, oil and gas, power generation, and transportation. They can be installed at emission sources, exhaust stacks, or integrated into environmental monitoring systems. Gas sensors enable continuous monitoring of emissions, helping industries comply with environmental regulations and optimize their operations to reduce pollution.

Benefits of Gas Sensor-Enabled Industrial Emission Monitoring:

Gas sensor-enabled industrial emission monitoring offers several benefits for industries, regulators, and the environment. Firstly, it helps industries identify and control emission sources, facilitating targeted pollution reduction measures. By pinpointing the sources of pollutants, industries can implement strategies to optimize processes, improve combustion efficiency, and reduce emissions.

Secondly, gas sensors aid in regulatory compliance by providing accurate and reliable emission data. Industries can monitor emissions in real-time, ensuring compliance with local and international emission standards. This enables proactive measures to avoid penalties, reputation damage, and potential legal consequences.

Furthermore, gas sensor technology helps industries improve energy efficiency and reduce operational costs. By monitoring emissions and combustion processes, industries can identify inefficiencies and take corrective actions to optimize energy use. This leads to cost savings and reduced carbon footprint, contributing to sustainable business practices.

Future Developments and Challenges :

Gas sensor technology is evolving rapidly, offering exciting future developments in industrial emission monitoring. Miniaturization and wireless connectivity enable the deployment of sensor networks, allowing for comprehensive and remote monitoring of emissions in large industrial complexes. Integration with data analytics and artificial intelligence enables advanced emission modeling, prediction, and optimization.

However, challenges need to be addressed to maximize the potential of gas sensor-enabled emission monitoring. Calibration and maintenance of gas sensors are critical to ensure the accuracy and reliability of emission data. Standardization of measurement protocols and data reporting formats is essential to facilitate data sharing and comparison between industries and regulatory agencies.

Moreover, as industrial processes become more complex, gas sensors should be capable of detecting and measuring a wide range of pollutants. Research and development efforts are necessary to enhance sensor selectivity, sensitivity, and response times for various gases and particulate matter.

Conclusion :

Gas sensor technology plays a pivotal role in unlocking insights into industrial emissions, aiding industries in monitoring and optimizing their pollution reduction efforts. By providing real-time data on emission concentrations, gas sensors empower industries to identify emission sources, comply with regulations, and improve energy efficiency.

With ongoing advancements and improvements in gas sensor technology, we can expect to see more accurate and reliable emission monitoring in the future. Integrated solutions with data analytics and artificial intelligence will enable more proactive pollution reduction strategies and predictive emission modeling.

By harnessing the potential of gas sensor technology, industries can mitigate the adverse effects of their emissions, contribute to cleaner air, and mo

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com