In industrial environments, the presence of hazardous gases poses significant risks to both human health and the environment. It is crucial to have effective gas detection systems in place to ensure the safety of workers and prevent potential accidents. Gas sensors play a vital role in real-time detection of hazardous gases, enabling prompt actions to mitigate dangers and protect lives. This article explores the importance of gas sensors in detecting hazardous gases, their working principles, and the advancements that make them indispensable in industrial safety.

Importance of Gas Sensors in Hazardous Gas Detection

Gas sensors are essential tools for monitoring the air quality in industrial environments. They detect the presence and concentration of various hazardous gases, including toxic gases, combustible gases, and volatile organic compounds (VOCs). The timely detection of these gases allows for swift response measures, such as evacuation, ventilation, or shutting down processes to minimize exposure and mitigate potential dangers.

The importance of gas sensors lies in their ability to provide real-time data on gas levels and trigger alarms when gas concentrations exceed safe limits. Early warning systems allow workers to take immediate action, preventing injuries, illnesses, or even fatalities. Additionally, gas sensors help identify potential gas leaks, faulty equipment, or unsafe conditions, contributing to the prevention of accidents and ensuring a safer work environment.

Working Principles of Gas Sensors

Gas sensors operate based on different principles depending on the type of gas they are designed to detect. The three common types of gas sensors are electrochemical sensors, catalytic bead sensors, and infrared sensors.

- Electrochemical Sensors: Electrochemical sensors utilize an electrochemical reaction between the target gas and an electrode to produce an electrical signal proportional to the gas concentration. These sensors are highly selective and sensitive, making them suitable for detecting gases like carbon monoxide (CO) and hydrogen sulfide (H2S). They require periodic calibration and replacement of the sensing element to maintain accuracy.

- Catalytic Bead Sensors: Catalytic bead sensors detect combustible gases using a heated wire coated with a catalyst. When combustible gases come into contact with the sensor, they undergo a combustion reaction, causing a change in the sensor's resistance. This change is measured and used to determine the gas concentration. Catalytic bead sensors are commonly used for detecting gases like methane (CH4) and propane (C3H8).

- Infrared Sensors: Infrared sensors detect gases by analyzing their absorption of specific wavelengths of infrared light. Each gas has a unique infrared absorption spectrum, which allows for precise identification and quantification. These sensors are commonly used for detecting hydrocarbons, carbon dioxide (CO2), and refrigerant gases. Infrared sensors provide accurate measurements and are less affected by cross-sensitivity to other gases.

Advancements in Gas Sensor Technology

Gas sensor technology has seen significant advancements in recent years, improving their performance, reliability, and versatility. Some notable advancements include:

- Miniaturization: Gas sensors have become smaller in size without compromising their sensitivity or accuracy. This miniaturization enables their integration into portable devices, wearable technology, and even drones, expanding their applications beyond fixed monitoring systems.

- Wireless Connectivity: Gas sensors now often feature wireless connectivity, allowing for remote monitoring, data logging, and real-time alerts. This capability enables instant notifications to relevant personnel, facilitating timely response actions regardless of their location.

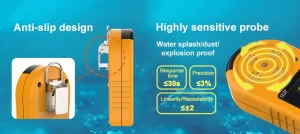

- Selectivity and Sensitivity: Gas sensors have become more selective, capable of distinguishing between different gases even in complex environments. They also exhibit higher sensitivity, detecting lower concentrations of hazardous gases and providing more accurate measurements.

- Smart Algorithms and IoT Integration: Gas sensors can now utilize smart algorithms and artificial intelligence capabilities for signal processing and data analysis. This integration allows for advanced gas detection pattern recognition, anomaly detection, and predictive analytics. Furthermore, gas sensors can be seamlessly integrated into the Internet of Things (IoT) networks, enabling centralized monitoring and control of multiple sensors in real-time.

Conclusion

Gas sensors play a vital role in the real-time detection of hazardous gases, ensuring the safety of workers and preventing accidents in industrial environments. By continuously monitoring gas levels and providing early warnings, gas sensors enable prompt actions to mitigate exposure, protect lives, and minimize environmental impacts. The advancements in gas sensor technology, including miniaturization, wireless connectivity, improved selectivity and sensitivity, and integration with smart algorithms and IoT, have further enhanced their capabilities and made them indispensable tools for industrial safety. As technology continues to evolve, gas sensors will continue to advance, providing even more accurate, reliable, and efficient detection of hazardous gases, contributing to safer and healthier work environments.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com