Workplace safety is of utmost importance to ensure the well-being of employees and the smooth operation of businesses. Among the various hazards that can pose risks to workers, gas leaks are particularly dangerous and can have severe consequences. Integrating gas sensors into workplace safety systems has become an effective approach to detect and prevent gas-related incidents. This article aims to explore the significance of gas sensor integration in promoting workplace safety, its functionality, benefits, and future prospects.

- Importance of Gas Sensor Integration in Workplace Safety: Gas leaks in the workplace can lead to fires, explosions, asphyxiation, and other hazardous situations. Industries such as manufacturing, oil and gas, chemical plants, and laboratories are particularly susceptible to gas-related incidents. Detecting gas leaks early is crucial to ensure timely evacuation, prevent accidents, and minimize the potential for injuries or fatalities. Gas sensors play a vital role in monitoring the presence of hazardous gases, providing immediate alerts, and enabling prompt actions to mitigate risks.

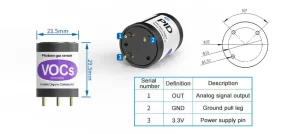

- Introduction to Gas Sensors: Gas sensors are devices designed to detect the presence and concentration of specific gases in the surrounding environment. They operate based on various principles, including electrochemical, semiconductor, catalytic, and infrared technologies. Common types of gases monitored by gas sensors include combustible gases (such as methane, propane), toxic gases (such as carbon monoxide, hydrogen sulfide), oxygen levels, and volatile organic compounds (VOCs). These sensors can be integrated into fixed monitoring systems or portable devices, facilitating continuous monitoring or spot checks.

- Functionality and Operation of Gas Sensors: Gas sensors work by measuring changes in electrical conductivity, changes in resistance, or the absorption of infrared radiation caused by the presence of target gases. The sensors convert the detected gas concentration into an electrical signal, which is then processed and analyzed to determine gas levels. Some gas sensors are designed to provide real-time readings, while others may be set to trigger alarms when gas concentrations exceed pre-set thresholds.

- Benefits of Gas Sensor Integration in Workplace Safety: 4.1. Early Gas Leak Detection: Gas sensors can detect gas leaks at their earliest stages, allowing prompt actions to be taken before the concentration reaches hazardous levels. Early detection enables evacuation procedures to be activated, reducing the risk of injuries and property damage.

4.2. Real-time Monitoring and Alerts: Gas sensors provide continuous monitoring of gas levels, ensuring that any sudden change or increase in concentration is immediately detected. Real-time alerts can be sent to safety personnel, enabling them to respond swiftly and appropriately to mitigate risks.

4.3. Improved Response Time: By integrating gas sensors with automated safety systems, emergency responses can be streamlined. For example, gas sensor integration with fire suppression systems can trigger the release of extinguishing agents in the event of a gas leak, minimizing fire risks.

4.4. Enhanced Safety Measures: Gas sensor integration facilitates the implementation of preventive measures such as proper ventilation, gas leak mitigation systems, and employee training programs. With accurate and timely data provided by gas sensors, safety protocols can be developed and enforced effectively.

4.5. Regulatory Compliance: Many industries are subject to strict regulations regarding workplace safety, including gas leak detection. Integrating gas sensors ensures compliance with these regulations, allowing businesses to avoid penalties and maintain a safe working environment.

- Future Prospects and Challenges: The field of gas sensor integration in workplace safety is evolving rapidly, driven by advancements in sensor technology, connectivity, and data analytics. Future developments may include the integration of gas sensors with Internet of Things (IoT) platforms, enabling remote monitoring, data sharing, and centralized control. Additionally, the use of artificial intelligence and machine learning algorithms can enhance the accuracy of gas leak detection, reduce false alarms, and enable predictive analysis for proactive maintenance.

However, challenges remain in the widespread adoption of gas sensor integration. These include the cost of sensor devices, calibration requirements, and ensuring compatibility with existing safety systems. Furthermore, the training of employees on gas safety protocols and the interpretation of sensor data is essential for effective implementation.

Conclusion: Integrating gas sensors into workplace safety systems is a critical step in promoting a safe and healthy working environment. By detecting gas leaks early and providing real-time alerts, gas sensors significantly reduce the risk of accidents, injuries, and property damage. As technology continues to advance, gas sensor integration holds great promise for improving workplace safety measures. By embracing these innovative solutions, businesses can ensure the well-being of their employees, comply with regulatory requirements, and safeguard their operations against potential gas-related hazards.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com