Gas sensors play a crucial role in various industries and applications, including environmental monitoring, industrial safety, and indoor air quality control. These sensors detect the presence and concentration of specific gases in the environment, providing valuable information for decision-making and ensuring safety. In this article, we will explore three key characteristics of gas sensors: sensitivity, selectivity, and response time.

Sensitivity:

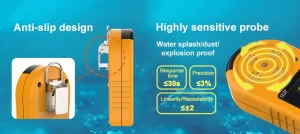

Sensitivity is one of the most critical characteristics of a gas sensor. It refers to the ability of the sensor to detect low concentrations of a target gas accurately. A highly sensitive gas sensor can detect even trace amounts of a gas, making it suitable for applications where early detection is crucial. Sensitivity is typically measured in parts per million (ppm) or parts per billion (ppb), indicating the minimum concentration of gas that the sensor can detect reliably.

To achieve high sensitivity

gas sensors employ various technologies, such as electrochemical sensors, semiconductor sensors, and optical sensors. Each technology has its advantages and limitations regarding sensitivity. For instance, electrochemical sensors are known for their high sensitivity to specific gases like carbon monoxide (CO) and hydrogen sulfide (H2S). On the other hand, semiconductor sensors offer excellent sensitivity to volatile organic compounds (VOCs).

Selectivity:

Selectivity refers to the ability of a gas sensor to respond specifically to a target gas while ignoring other interfering gases present in the environment. In real-world scenarios, multiple gases may be present simultaneously, and distinguishing between them is crucial for accurate gas detection. A gas sensor with high selectivity ensures reliable and precise measurements by minimizing false alarms and cross-sensitivity.

Various methods are employed

to enhance the selectivity of gas sensors. One common approach is to use specific sensing materials that react selectively with the target gas. Additionally, advanced signal processing techniques, such as pattern recognition algorithms, can be employed to differentiate between different gas signatures, further improving selectivity.

Response Time:

Response time is another essential characteristic of gas sensors, representing how quickly the sensor can provide a measurable response to the presence of a gas. The response time includes both the rise time (the time taken by the sensor to reach the desired output level) and the recovery time (the time taken to return to the baseline level after gas removal). A fast response time is crucial in applications where immediate detection and response are required, such as leak detection or safety monitoring.

The response time of gas sensors

depends on several factors, including the sensor technology, the type of gas being detected, and environmental conditions. For example, catalytic bead sensors offer fast response times for combustible gases, making them suitable for explosive gas detection. On the other hand, some electrochemical sensors may have longer response times but offer high accuracy and stability for certain gases like ozone (O3) or nitrogen dioxide (NO2).

Conclusion:

Gas sensors with high sensitivity, selectivity, and fast response times are essential for various applications, ranging from industrial safety to environmental monitoring. By accurately detecting and quantifying specific gases, these sensors contribute to ensuring workplace safety, maintaining air quality, and preventing potential hazards. As technology advances, continuous research and development efforts aim to improve the performance and characteristics of gas sensors, making them even more reliable and efficient in gas detection applications.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com