Background:

On the job, do you know that your gas detectors will protect you? Do you have the right equipment to keep you safe and get the job done? With so many options on the market, it can be overwhelming to know what gas detectors will meet your needs.

Proper training on devices is crucial. When you enter a potentially dangerous situation, you need to be aware of the risks and how your gas detector can help. You can reduce confusion onsite by ensuring you have the right monitor, designed to only alert in the presence of the gas you want to detect. A worker may be more likely to listen to that monitoring alarm and evacuate if they know that their equipment is working for them on the job.

You don’t have the time to waste—find which portable gas detectors are best to protect your people and help get the job done.

Single VS Multi-Gas Monitor

Companies often use different gas detectors for different teams: temporary contractors use single gas detectors, full-time employees use multiple gas detectors, and professional teams use more advanced gas detectors. With so many options, it can be hard to know that your employees are using the best equipment for the job. It's important to know that different gas monitors offer different capabilities, and some monitors may be more useful to your application than others.

To find the right monitor for your team, you first need to understand the operational differences between gas detectors. Things can get dangerous if you use the wrong gas monitor.

The features people look for in a gas monitor can fluctuate as the business changes. Large refineries with hundreds of employees typically focus on hydrogen sulfide and may be looking for a single gas monitor to detect it. But when something goes wrong -- carbon monoxide exposure, lack of oxygen, or something like that -- the needs change. As the safety culture within your company or industry changes, you may need to use a different gas monitor.

Portable 4 in 1 Gas Detector

Among the currently available gas monitors, the JXCT@Portable 4 in 1 Gas Detector is one of the most popular. This quad gas monitor has the portability and size of a single gas monitor. It's light but sturdy.

In more specialized health and safety teams, advanced monitoring comes into play when the situation becomes more complex. For example, in the case of confined spaces, many questions arise around the topic of safety: Are you only concerned about a specific gas, or are there unknown factors to deal with? Is there a sensor that can catch something crazy? Can you reliably send your employees into this situation using a standard four-gas monitor and know that these are all they have to worry about?

Advanced monitoring may not be relevant on a day-to-day basis, but it is the first check in a series of security protocols and remains critical. Advanced monitoring anticipates the unexpected, so your employees aren't caught in suddenly dangerous situations.

Connectivity and Advanced Monitoring

When you're at work, it's critical to stay connected with your team, whether in person or remotely. Connectivity is key when you need to share important information in real time.

Newer networked personal monitors and area monitors can share gas readings and alerts for in-person, team-based safety. Two workers using connected gas detectors can create a localized peer-to-peer security group. When one worker's alarm goes off, the other worker's alarm goes off. Connected gas detectors can also transmit hazard information to the cloud in real time, allowing security managers to see alerts and data messages as they occur.

You don't have to be in a certain industry to benefit from these connectivity features. Typically, larger chemical plants, refineries and even fire departments incorporate connectivity into their safety plans, but other industries can benefit from it as well. Here's the next step: everyone wants to have it, but you need to make sure the connection will benefit your company and your employees.

When you rely on gas detection equipment for your day-to-day tasks, you need to be sure that you are using a monitor that will keep you safe on the job. Hazards vary by industry, but safety should remain consistent. You need the right equipment, and choice is an important one: it ultimately comes down to finding the right feature set in a gas detector that best meets your needs and keeps you safe.

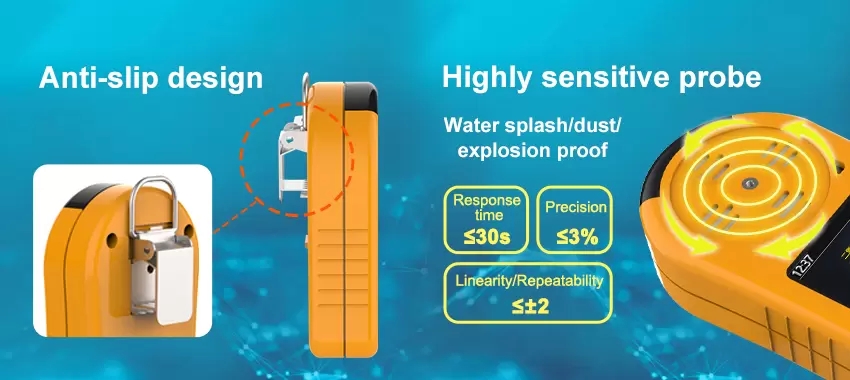

NO2/NO gas detector

Portable NOx sensors, NO/NO2 detector, are used in gas storage leakage monitoring, drug factory, food factory, hospital gas disinfection residue detection, electrostatic precipitator, gas generator, air purifier, gas leakage, indoor air gas detection scene.Principles of mechanics and humanized design The anti-slip design is based on the principle of human mechanics to ensure product sensitivity and accuracy. Enhance the comfort of the human body and conform to the operating habits of the human body.More gas monitoring equipment welcome to consult JXCT

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com