Summary

NDIR gas Analyzers employ the use of specialized infrared gas sensors to measure the concentration of the measured gas in the surrounding air. This overview from JXCT outlines how they work, what gases they measure, and why they are essential for many industrial applications.

Gases Analyzed by NDIR Analyzers

NDIR gas Analyzers accommodate the analysis of a wide range of gases, including carbon dioxide (CO2), carbon monoxide (CO), methane (CH4), and sulfur dioxide (SO2). Below we outline how NDIR analyzers are used to analyze these gases in different industrial applications.

CO2 Analyzers

Many industrial facilities rely on CO2 analyzers to monitor air quality conditions to ensure gas levels remain within a set limit. Typical applications include use in the following:

Combustion operations: Combustion occurs in various industrial equipment and systems, such as boilers, furnaces, and heaters. CO2 analyzers can be used to determine system performance and efficiency, allowing industry professionals to identify opportunities for system optimization.

Landfill operations: In landfills, the anaerobic decomposition of waste generates CO2. These gas emissions can be harnessed for energy but must first be analyzed for suitability in engines. CO2 analyzers enable industry professionals to determine whether gas will burn efficiently.

Agriculture/food storage operations: CO2 is critical in the production and storage of fresh produce. Many companies maintain controlled environments with low oxygen and high CO2 levels to promote plant growth and reduce the risk of contamination, degradation, and infestation of picked produced.

CO2 analyzers enable them to ensure CO2 remains at the desired levels.

Fire suppression operations: When designing and building fire suppression systems, manufacturers use CO2 analyzers in controlled suppression experiments. The data gathered for these experiments provides insight on how to suppress fires in specific hazard scenarios.

CO Analyzers

CO AnalyzerSimilar to CO2, CO is a by-product of combustion operations and toxic in high quantities. As such, CO analyzers that employ infrared and electrochemical sensors find application in many industrial operations, including the following:

Steel-making operations: CO is released when steel or other carbon-containing materials are heated and cooled. As the amount of CO released during this process is an indication of product and production quality, knowing the concentrations can facilitate the implementation of optimization efforts.

Gasification operations: Gasification converts organic matter into CO in low-oxygen environments. The resulting gas can then be used as fuel. Since the process requires a controlled amount of oxygen, accurate concentration measurements are critical.

CH4 Analyzers

CH4—also commonly known as methane—is a more potent greenhouse gas than CO2. As it is combustible, it is often used in energy generation operations. Some common use cases for CH4 analyzers include biogas, landfill, and syngas operations.

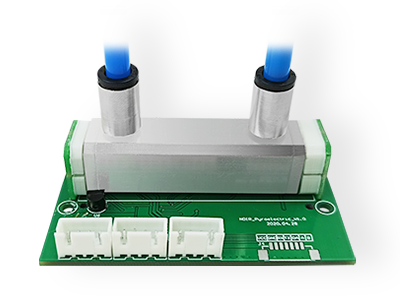

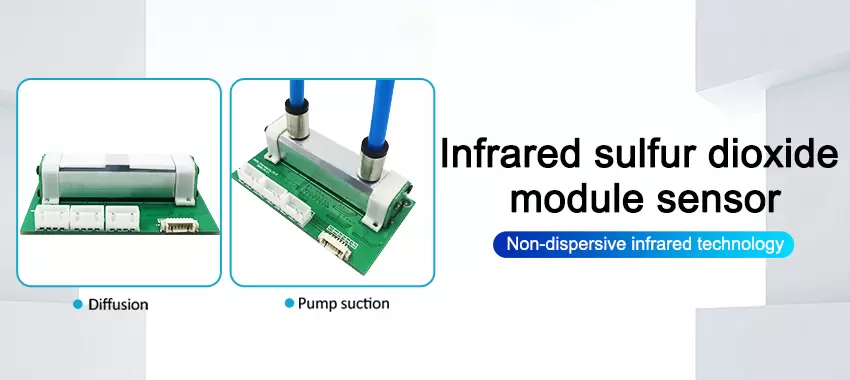

SO2 Analyzers

This type of SO2 analyzer allows for continuous analysis of sulfur dioxide levels in process gas streams. Typical applications include use in chemical plants, power plants, and other industrial facilities.

Working Principle of NDIR Analyzers

As indicated by their name, NDIR gas Analyzers employ the use of infrared radiation to perform their function. In a typical NDIR analyzing operation, an infrared lamp directs infrared light toward the gas sample. The light passes through the gas particles and an optical filter into an infrared light detector. Once the detector receives the light, the concentration of a particular gas can be calculated.

How Are Gas Levels Calculated?

By analyzing the difference between the amount of infrared light of a particular wavelength generated by the lamp and the amount that reaches the detector, industry professionals can determine how much light is absorbed by the gas molecules. As many gases have unique absorption bands, knowing this factor allows them to identify the number of gas molecules present in the sample. The concentration can be indicated as a percentage (%) of the sample or in parts per million (PPM).

Why Use NDIR Analyzers?

NDIR gas Analyzers are suitable for measuring sample gases in both high and low concentrations. As they are highly durable, even when exposed to oxidizing compounds, they offer long service lives and low life-cycle costs.

Contact the Gas Analyzer Experts at JXCT

As indicated above, non-dispersive infrared (NDIR) analyzers play a critical role in many industrial applications. For all of your NDIR analyzer needs, turn to the experts at JXCT.

At JXCT, we have designed and manufactured high-quality gas analyzers for over 40 years. Our products include NDIR and other analyzers in portable, continuous, and sample conditioning models. For more information about our offerings, contact us or request a quote today.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com