Background:

A flue gas analyzer is a piece of equipment that manipulates flue gases for emissions and efficiency purposes, and can range from an inexpensive hand-held instrument to a larger unit in manufacturing where the flue is permanently installed. The analyzer has an internal memory system that stores the gas reading information until the actual values are fed into the computer system for further gas analysis.

The working of flue gas analyzers

The probe model is the most popular, and the flue gas analyzer does not necessarily need to use the probe to monitor the gas in the flue. For example, an analyzer can draw gas from a flue through a tube connected to the instrument.

Sometimes it takes more effort to accurately measure or monitor gases with a flue gas analyzer because some gases, such as hydrogen chloride or sulfur dioxide, require proper heating of the tubes connected to the analyzer. Heated tubes prevent some gases from condensing into liquids before measurement. Some gases need to be cooled using an instrument called a Peltier cooler, which cools the gas for further manipulation. Peltier coolers cool the surface so the tubes can transport the gas to the analyzer where any moisture in the gas is removed before it is measured. With an MRU instrument, you can measure a company's pollution data to see if their equipment emits harmful gases into the air, causing pollution.

JXCT's flue gas monitoring equipment

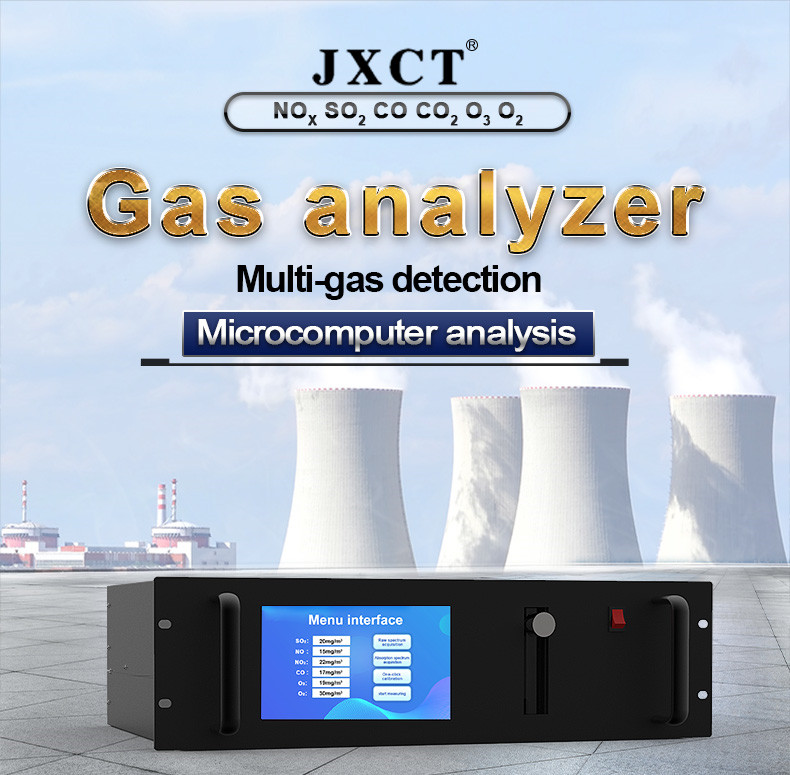

Gas analyzer is a gas sensor independently developed by Jingxun Unimpeded using different detection principles for multi-gas detection. The gas detector adopts microcomputer analysis, which can detect the concentration of NOx, SO2, CO2, CO, O3 and O2. Gas analyzer is suitable for gas detection in thermal power plant, steel plant, non-ferrous metal smelter, aluminum smelter, cement plant, phosphate fertilizer plant, nitric acid plant, sulfuric acid plant, petrochemical, chemical fiber, industrial furnace, boiler, civil heating boiler and other occasions.

Industrial VOC Analysis and Monitoring

The volatile organic compound online monitoring system (VOC online monitoring) can be used to monitor the unorganized emission of volatile organic compounds in the plant boundary and park. The VOC gas monitoring system can be used to determine the total hydrocarbons, methane, non-methane total hydrocarbons, and benzene in the ambient air.

The concentration of toluene, xylene and characteristic pollutants; monitoring data can be transmitted to the monitoring center in real time to realize the management functions of pollutant data display, alarm management and data analysis. At the same time, it can provide customized solutions for a variety of different working conditions and customer needs.

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com