Background:

Volatile organic compounds (VOCs) are widely used in industry and pose a significant hazard to human health. What are VOCs, their role in industry, and the importance of VOC detectors for maintaining industrial hygiene.

What are Volatile Organic Compounds?

For chemists, an organic compound is any chemical substance that contains one or more carbon-hydrogen bonds. This broad class of compounds is so named because it makes up many of the molecules on which life depends—including DNA, proteins and sugars. A compound is considered volatile if it has a high vapor pressure at room temperature. If a compound has a high vapor pressure, it evaporates easily and diffuses into the surrounding air.

Therefore, a volatile organic compound or VOC is any compound that contains carbon-hydrogen bonds and is also prone to vaporization. Naturally, the class of compounds is quite broad, with many relatively harmless chemicals produced by healthy plants and animals.

However, many VOCs produced or used in industry present serious health risks. Common examples of hazardous industrial VOCs include benzene, ethylbenzene, styrene, toluene, and xylene. In common usage, the term "VOC" is a convenient way of grouping these various compounds together. The chemical similarity means that VOC detectors are able to measure the levels of many of these compounds as a whole.

VOC detectors minimize health risks

Exposure to varying concentrations of VOCs can have a variety of acute and chronic health effects. The most common symptoms of exposure are acute and include eye and/or throat irritation, dizziness, nausea and, in rare cases, loss of consciousness or death.

The chronic effects of long-term exposure to VOCs can be severe. These include damage to internal organs such as the liver and kidneys, damage to the endocrine system and central nervous system, and cancer. That's why VOC detectors must be used to protect personnel exposed to industrial environments.

Occurrence of industrial VOCs

VOCs exist in many forms in modern industry. They are widely used as industrial solvents, fuel oxygenates, and refrigerants; also appear in the manufacture of paints, pharmaceuticals, and hydraulic fluids.

Due to their potential hazards and their ubiquity in almost all industrial sectors, VOCs are a major concern in industrial hygiene and indoor air quality. Therefore, the use and production of VOCs is regulated by law, especially in indoor environments where concentrations can reach higher levels. VOC detectors are an essential part of industrial hygiene. VOC detectors come in a variety of designs and can be tailored to suit different applications according to the specific needs of where the technology will be used.

Fixed VOC detector

Fixed VOC monitors are often deployed where specific VOC hazards are present. For example, a fixed VOC monitor might be installed in a factory where a process step uses volatile organic solvents. Larger facilities often choose to install site-wide networked addressable VOC detectors, while small system VOC detectors provide a good solution for smaller areas.

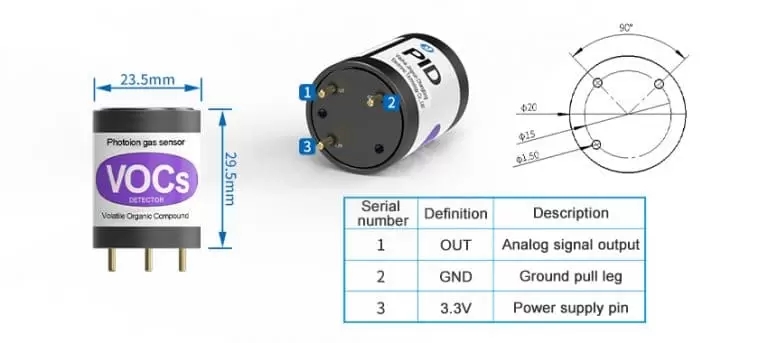

VOC sensor-PID Photoionization Detectors

The PID photoionization probe& pid sensor realizes rapid detection of VOC gas, is waterproof, easy to clean, durable, multi-range selection, and accurate measurement. PID module is high sensitive and quick react. It can help you alarm the VOC at the first time and make sure your health

: +86 155 8830 2704

: +86 155 8830 2704 : jxdziot@gmail.com

: jxdziot@gmail.com